Turns out motor racing might be useful after all

The Formula 1 Championship is a strange beast. I’m not alone in having become thoroughly bored with the political wranglings around it, and I’ve drifted far enough away that I no longer even recognise most of the team names. So it’s something of a surprise to learn that the engineering work going on behind the scenes might still be – whisper it – relevant and useful.

Burning petrol in a car engine is fairly mad in the grand scheme of things, partly because internal combustion engines are horribly inefficient. They typically bumble along around the 20 or 25 per cent thermal efficiency mark: only one fifth or so of the energy input (in the form of petrol) is turned into useful work. That’s not necessarily a great surprise if you look at everything that’s going on inside an engine – click the picture for a brilliant Animagraffe page illustrating the four-stroke engine cycle. Car engines get hot, and that heat isn’t doing anything to propel you down the road.

Diesel engines can head up towards 40% efficiency, but even as recently as 2014 it was big news when Toyota managed to hit 38% for a petrol engine, which I think is the one currently in their latest Prius hybrid.

So a rumour that the Mercedes and Ferrari F1 teams have petrol engines that achieve somewhere around 47% efficiency is eye-catching. They’re managing this thanks to German engine component supplier Mahle, whose design adds a secondary combustion chamber linked to the main cylinder head. The spark plug ignites a fuel-rich mixture in that secondary chamber, blasting a turbulent jet of burning gases into the leaner mixture in the cylinder. That leads to more complete combustion, and hence a more efficient engine overall.

Now, internal combustion engines are at their most efficient when they’re operating under load (ie. accelerating) and with the throttle full open (ie. accelerating hard). Which is more like the typical situation for Formula 1 engines than a daily commute, bumbling along in nose-to-tail traffic. So gains at the racing circuit don’t necessarily mean as much on the public road. Nevertheless, the thought that there are still major gains to be wrung out of old engine technology is surprising, and encouraging. Maybe we’ll see some of these ideas in road cars in the not-too-distant future?

Read more about the ‘Turbulent Jet Ignition” technology in this excellent Ars Technica article.

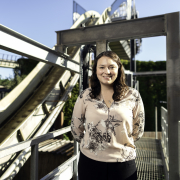

In fact, engine technology remains a huge field of research. Here’s engineer Hannah Petto giving a behind-the-scenes peek of the engine test facilities at Caterpillar’s engine research site, here in the UK, outside Peterborough:

The racing teams may have all the showy glamour, but there’s similar sorts of work going on for construction and agricultural machinery.

Not-so-coincidentally, the Think Physics office is currently reverberating to the sound of power tools and hydraulic hammers, as the building here at Northumbria University is being partially rebuilt to accommodate – amongst other things – a new engine test facility similar to the one Hannah shows in the film. It’ll be used to help deliver the new Automotive Engineering degree course we have starting up here from September this year.

The future may rest in electric vehicles, but we’re a long way from done with internal combustion.

Leave a Reply

Want to join the discussion?Feel free to contribute!